Home > Products > Stainless steel sheet > 321 stainless steel sheet

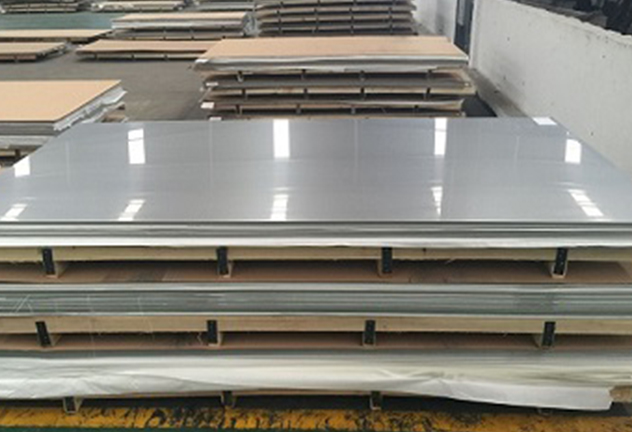

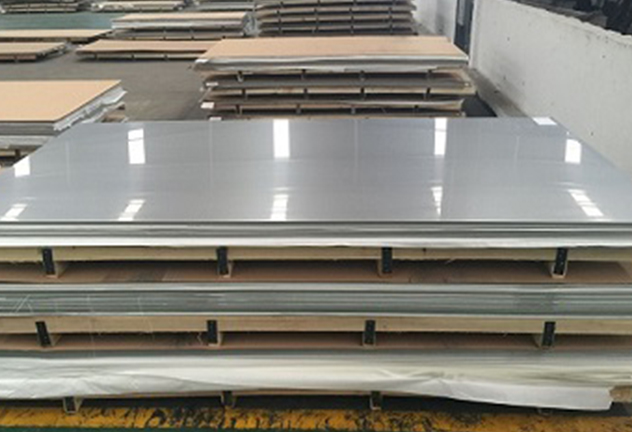

321 stainless steel sheet

Corrosion Resistance

Type 321 stainless steel has similar corrosion behavior to Type 304 with the exception of improved intergranular corrosion resistance due to the titanium addition for stabilization. Resistance to organic acids and some inorganic acids is excellent. However, long term exposure to temperatures between 900 – 1500 °F (482 – 816 °C) may reduce its overall general corrosion resistance but remains improved compared to unstabilized grades.

Formability

Type 321 can be readily formed and drawn, however, higher pressures are required and more springback is encountered than for carbon steel and ferritic stainless steels. Like other austenitic stainless steels, Type 321 work hardens quickly and may require annealing after severe forming.The presence of certain alloying elements can make

Type 321 more difficult to form than other austenitic grades such as 301, 304 and 305.

Weldability

The austenitic class of stainless steels is generally considered to be weldable by the common fusion and resistance techniques. Special consideration is required to avoid weld ”hot cracking” by assuring formation of ferrite in the weld deposit. This particular alloy is generally considered to have comparable weldability to Types 304

and 304L. A major difference is the titanium addition that reduces or prevents carbide precipitation during welding. When a weld filler is needed, either AWS E/ER 347 or E/ER 321 is most often specified. Type 321 is well known in reference literature and more information can be obtained in this way.

Heat treatment

Type 321 is non-hardenable by heat treatment. Annealing: Heat to 1750 – 2050 °F (954 – 1121°C), then water quench or air cool.

Application

Aircraft exhaust stacks,Manifolds,Chemical processing equipment,Welded equipment,Jet engine parts

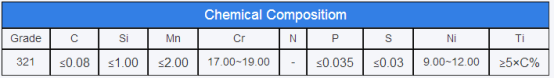

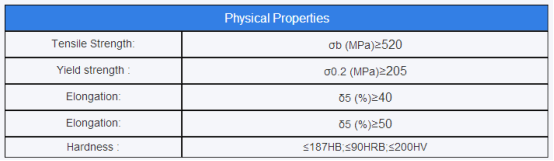

Properties:

Back to list

Back to list