Home > Products > Stainless steel sheet > 316L Stainless Steel Sheet

316L Stainless Steel Sheet

CORROSION RESISTANCE

Types 316 and 316L Stainless Steels ex-hibit better corrosion resistance thanType 304. They provide excellent pitting resistance and good resistance to most chemicals involved in the paper, textile and photographic industries

HEAT TREATMENTS

Types 316 and 316L are non-hardenable by heat treatment.Annealing: Heat to 1900 - 2100°F(1038 - 1149°C), then rapidly quench.

FORMABILITY

Types 316 and 316L can be readily formed and drawn.

WELDABILITY

The austenitic class of stainless steels is generally considered to be weldable by the common fusion and resistance techniques. Special consideration is re-quired to avoid weld ”hot cracking“ by assuring formation of ferrite in the weld deposit. These particular alloys are

generally considered to have poorer weldability than Types 304 and 304L. Amajor difference is the higher nickel content for these alloys which requiresslower arc welding speed and more care to avoid hot cracking. When a weld filler is needed, AWS E/ER 316L and 16-8-2

are most often specified. Types 316 and its low-carbon ”L“ version are well known in reference literature and more information can be obtained in this way.

APPLICATION

Typical uses include exhaust manifolds,furnace parts, heat exchangers, jet engineparts, pharmaceutical and photographic equipment, valve and pump trim, chemical equipment, digesters, tanks,evaporators, pulp, paper and textile processing equipment, parts exposed to marine atmospheres and tubing.

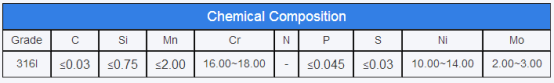

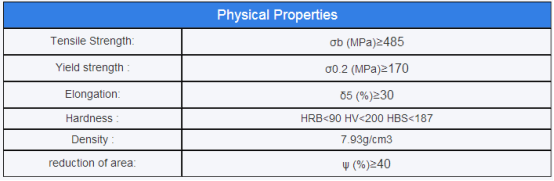

Properties:

Back to list

Back to list