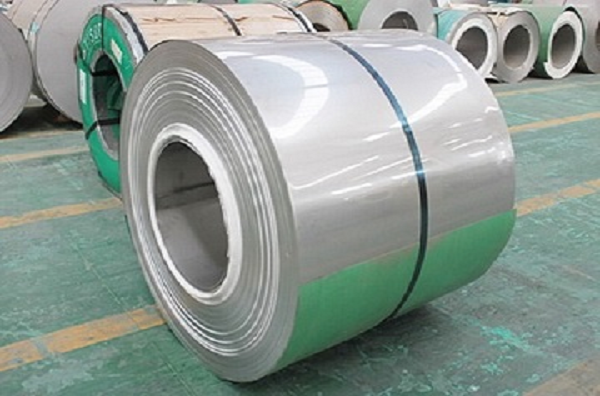

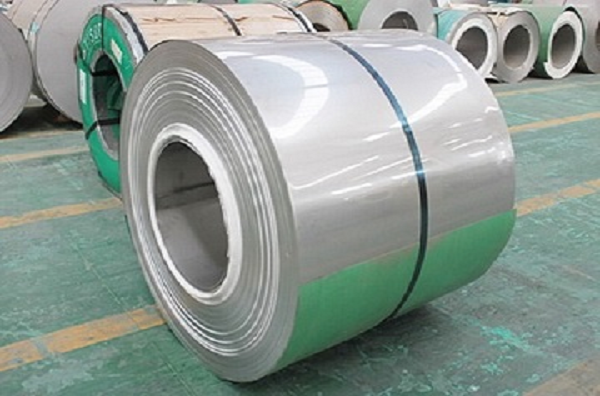

Home > Products > Stainless steel coil & strip > 310s stainless steel coil

310s stainless steel coil

310/310S stainless steel is a highly alloyed austenitic stainless steel designed for elevated-temperature service. The high Cr and Ni contents enable this alloy to resist oxidation in continuous service at temperatures up to 1200°C, provided reducing sulfur gases are not present. In intermittent service, it can be used at temperatures up to 1030°C as it resists scaling and has a relatively low coefficient of expansion. This alloy has superior resistance, compared to both SS 304 and SS 309, in carburizing and reducing environments. SS 310 types are used for their high-temperature oxidation resistance in applications such as furnace parts, mufflers, radiant tubes, and ammonia converters.

• Resistant to oxidation in continuous service at temperatures up to 1200°C (provided reducing sulfur gases not present)

• Superior resistance in carburizing and reducing environments

• Can be deep drawn, stamped, headed, and upset without difficulty

Common Applications

• Furnace parts and shafts

• Muffles

• Radiant tubes

• Ammonia converters

• Carbon Saggers

• Power Boiler Tube Hangers

• Brazing fixtures

• Glass forming equipment

• Chemical Process Industry

• Food Processing

General Characteristics The austenitic stainless steel 310S (UNS S31008/AISI310S) has about 25% Cr, 0,6 % Si and 20% Ni. This grade is known for its behavior of corrosion resistance at high temperature. The additions of carbon are optimized in order to improve its creep deformation resistance. The steel can easily be welded. AISI 310S is projected for high temperature applications, up to 1100°C, in oxidating atmospheres. The steel can also be used under conditions of slightly oxidating atmosphere, nitriding, cementation and sulfuring as well as with thermal cycles, although temperature must be reduced. This stainless steel is widely used in the thermal treatment industry for parts of furnaces, such as refractories support, parts of burners, conveyor belts, furnace lining, fans, etc.; in the food industry, they are used in contact with heated citric and acetic acids.

Properties:

Back to list

Back to list